Plastic/Rubber Recycling Plant

Plastic/Rubber Recycling Plant

Our planet is drowning in plastic pollution.

Today we produce about 300 million tones of plastic waste every year. Researchers estimate that more than 8.3 billion tones of plastic has been produced since the early 1950s. About 60% of that plastic has ended up in either a landfill or the natural environment. We’re seeing some other worrying trends. Since the 1950s, the rate of plastic production has grown faster than that of any other material. We’ve also seen a shift away from the production of durable plastic, and towards plastics that are meant to be thrown away after a single use.

More than 99% of plastics are produced from chemicals derived from oil, natural gas and coal — all of which are dirty, non-renewable resources. If current trends continue, by 2050 the plastic industry could account for 20% of the world’s total oil consumption.

We need to slow the flow of plastic at its source, but we also need to improve the way we manage our plastic waste.

Only 9% of all plastic waste ever produced has been recycled. About 12% has been incinerated, while the rest — 79% — has accumulated in landfills, dumps or the natural environment.

But the world is waking up to the problem, and governments are starting to act.

We are develop and implement own technology into operation to turn the waste problem into income.

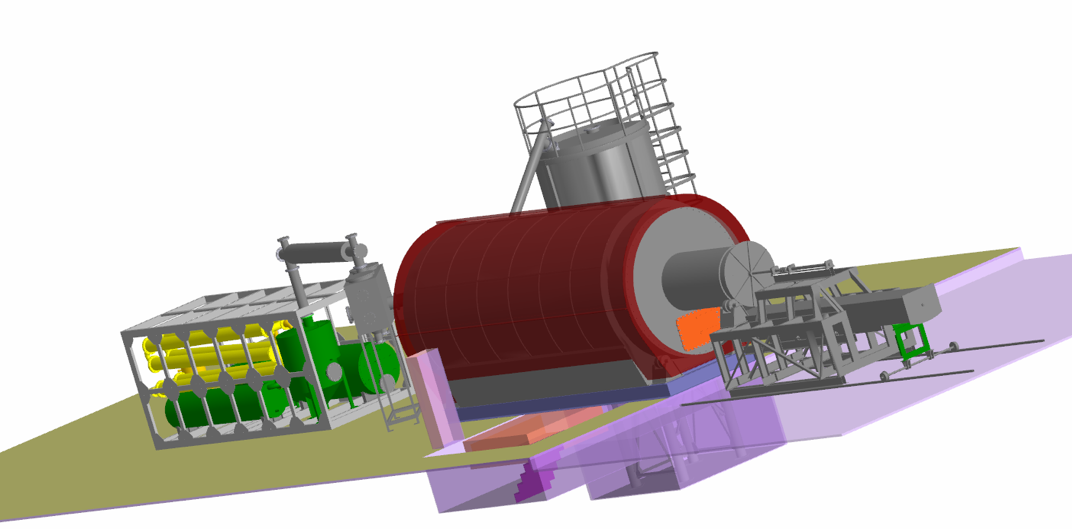

Our technology is a low-temperature thermal decomposition process without oxygen.

Our technology allows to recycle plastic and rubber waste into fuel oil, technical carbon and gas which can be used for the further production.

• This Project has received funding GRANT from the European Union’s Horizon 2020 research and innovation program

• Project also awarded with the Seal of Excellence from European Commission. The 'Seal of Excellence' is a quality label awarded to projects submitted to the Horizon 2020 SME Instrument

• Project was received ETRA (The European Tyre Recycling Association) Letter of Support

• a cooperation agreement was signed with Tallinn University of Technology (TalTech) shale oil competence center, whose experts highly appreciated the capabilities of our pyrolysis equipment.

• Pyrolysis – decomposition of raw materials (wastes) at high temperature and pressure, Low-temperature thermal decomposition process without oxygen – pyrolysis process, modified by our experts.

• Full Automation means safety

• Modular design of the installation, which ensures high mobility and the absence of the need for a special foundation which greatly simplifies the installation of equipment

• Quick commissioning of the installation from the moment of conclusion of the contract

• Use in the production of high-quality materials and components: the reactor drum made of chemically resistant heat-resistant steel

• Virtually no preliminary work on plastic – reduces costs;

• Virtually no waste process

• Self-sufficient, low-cost, low-consumption process

• Ecologically clean

• Differs from the traditional by:

• Low temperature, low pressure levels of the process;

• Modular design of the technological process;

• Automation System, fully controlling all the steps of the process;

• Level of Emissions Control.

Details

About UAB "KATILAITIS"

UAB Katilaitis is Association TIS GROUP representative in the Baltic States.

It is a joint Lithuanian and foreign capital company.

TIS GROUP Manufacturers Association was founded in 1992 and today has its representatives in Russia, Ukraine, Belarus, Poland, Hungary and the Baltic States.

.

CONTACTS

- Girulių str. 26A, Šiauliai, LT-78138, Lithuania

- Phone: +370 62015353

- Email: katilaitis@gmail.com